MY MÜLLTONNE

SKU:32969299361877

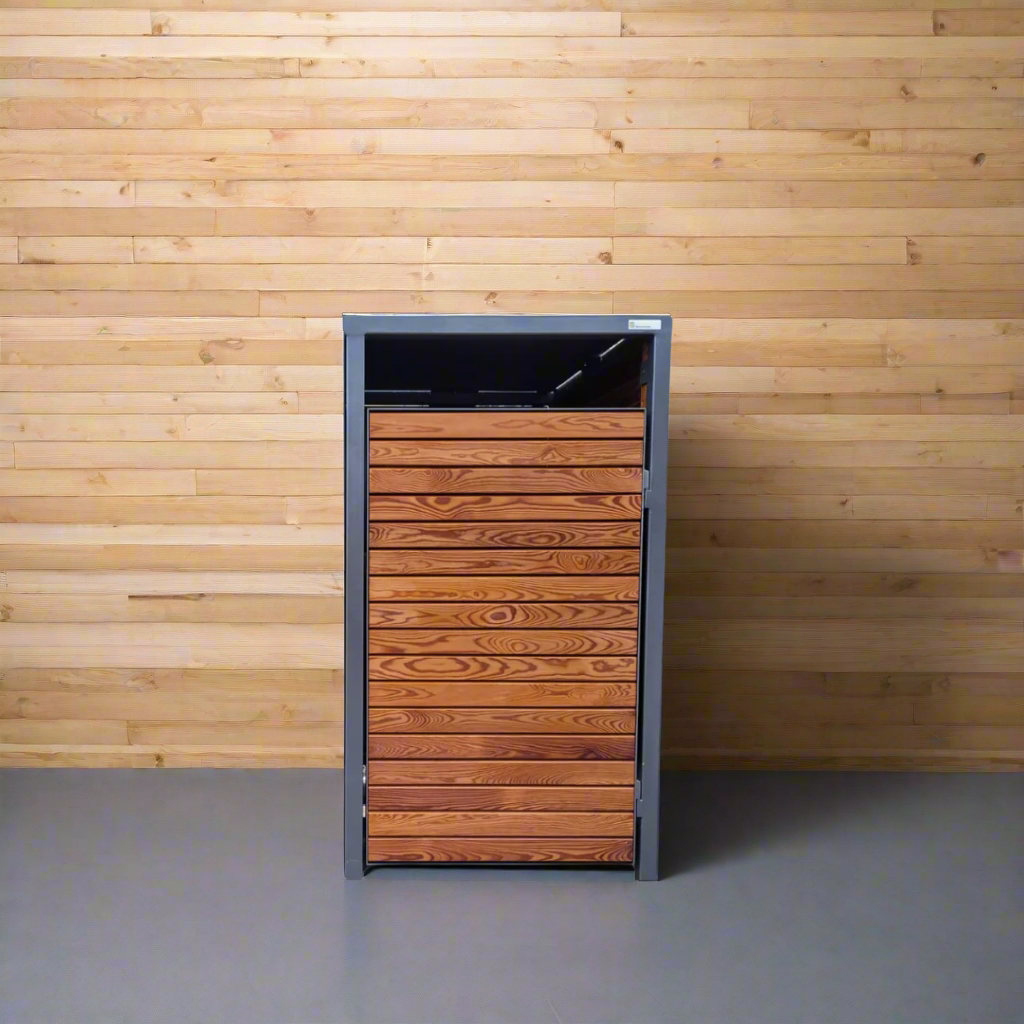

<tc>PREMIUM wooden 1-bin garbage bin box</tc>

<tc>PREMIUM wooden 1-bin garbage bin box</tc>

Couldn't load pickup availability

Product information premium wood 1-bin garbage bin box

The super high-quality garbage bin box with wooden doors offers space for a 120 liter or 240 liter wheelie bin.

The great look is rounded off with a flatroof or planter roof. All common wheelie bins according to DIN or EN have space to fit easily into the garbage bin box.

PRODUCT FEATURES

- Extremely high-quality processing and durable, robust material

- Unique price-performance ratio ONLY at MyMülltonne

- Highest quality, top design, made in Germany

- Individual design options with different colours

- Easy to use thanks to the "MyMülltonne principle"

- Delivery is fully assembled

- No anchoring to the ground required

TECHNICAL SPECIFICATIONS:

120 liter boxes:

|

Number of bins |

1 garbage bin |

| Width | 65cm |

| Depth | 73 cm |

| Height (flat roof) | 113cm |

| Weight (flat roof) | approx. 52kg |

240 liter boxes:

|

Number of bins |

1 garbage bin |

| Width | 71cm |

| Depth | 83 cm |

| Height (flat roof) | 126cm |

| Weight (flat roof) | approx. 66kg |

The robust frame, including the doors of the garbage bin box, is made of tubular steel with a square profile (3 mm) which is then hot-dip galvanised. The metal sheets with which the garbage bin box is clad have a thickness of 1.5 and 2 mm.

The extremely robust material selected ensures the highest resilience and long service life of the garbage bin box. All components, frames and galvanised sheets are then powder-coated with a German powder paint. You have a standard choice of RAL 7016 anthracite, DB 703 metallic iron mica or RAL 9006 light gray metallic. Of course, we can manufacture all your colour requests for a small additional charge.

The high-quality powder coating gives the bin box the colour finish, an elegant look, makes it durable and offers protection from wind and weather. All connections are made with aluminium-zinc rivets, which are also coated in the colour of the sheet metal so that they are not noticeable.

The garbage bin box owes its high resilience and long service life to a complex process in which the garbage bin box is given a high-quality double coating. In the first step of the process, the material is hot-dip galvanised in an immersion bath. All parts are also protected from rust on the inside . After the "fine plaster", the so-called fine sanding of the surface, the powder coating is baked.The doors are fitted with a strong magnetic latch. The door stop is always on the left for a 1-bin box. On request, we can manufacture the door stops for you in any custom-made for a small additional charge.

The most important product features at a glance:

- Award-winning design, blends perfectly into your home

- Resilient in action, and heavy-duty

- Weather-resistant: construction made of hot-dip galvanised, powder-coated steel with doors in high-quality rhombus profile larch or thermal pine

- Easy handling thanks to the "MyMülltonne principle" (open the door - lift the lid - throw in the garbage bag)

- No assembly work: The box is delivered fully assembled

- Individual design options: we also manufacture in your desired RAL colour

Colours:

By default, the garbage bin box can be designed in one colour with the colours listed below, or multicoloured. For example, do you want the frames in RAL 9006 and the sheets in DB 703? - No problem. We can do that for you at no extra charge! In addition, custom-made products in construction and colour can be produced according to your individual ideas and wishes. Just get in touch with us and tell us your wishes.

Share